We are equipped with CNC machines from mainstream brands to ensure precision and stability. Our equipment portfolio includes approximately 25 machining centers, covering 3-axis, 4-axis, and 5-axis machining centers, as well as gantry machining centers and horizontal machining centers, to meet the equipment requirements for various parts.

Our precision grinding capability has always been a source of pride. Whether for round or square parts, mold steel or tungsten carbide, cutting tools for equipment or motor spindles, we have developed our own set of solutions.

We have 5 conventional lathes to handle single-piece product machining needs. Additionally, 8 CNC lathes are available, capable of processing small-batch materials with diameters ranging from 1mm to 300mm.

Equipped with Sodick wire cutting machines, we can machine small holes with a diameter of 0.1mm. We also have fast wire cutting equipment to meet customers’ low-cost requirements.

We have in-house laser cutting equipment. Our partners are equipped with high-power laser cutting machines, which can effortlessly cut steel plates up to 100mm thick.

Our bending technicians have over a decade of production experience and are equipped with a wide range of mold tools, capable of meeting customers’ requirements for special-shaped bending. Conventional bending accuracy can be controlled within ±0.1mm.

Our welding technicians have over ten years of production experience. Welding equipment includes argon welding, aluminum welding, gas shielded welding, laser welding, etc., to meet the diverse needs of customers across industries.

Dedicated to solving customer challenges, we have accumulated extensive external collaboration resources over nearly 20 years. We can complete more than 30 types of surface treatments to meet the needs of customers in different industries.

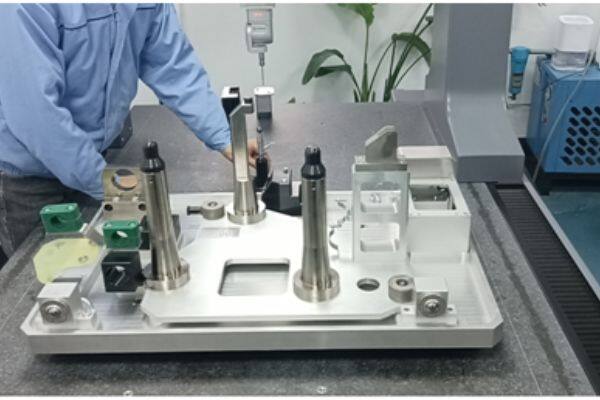

In accordance with customer requirements, every screw assembled by us undergoes inspection and marking. Our expertise in the form and position relationships of components, combined with our coordinate measuring machines, enables us to assemble and debug many precision components for customers.

Specializing in the processing and production of various types of precision mechanical parts.

Copyright © 2025 Suzhou DANVIE Precision Machining Co., Ltd.